Manufacturing Process

Dyeing is the process of transforming grey yarn into coloured yarn through the use of colour substances. The factors to be considered to obtain a perfect dyeing uniformity are, the penetration of the dye and stability. It is essential that the fabric retains the original colour even after repeated washings.

Divided into several phases, the dyeing is the working process for the transformation of the raw greige yarn into coloured yarn, through the use of colouring substances. Determining factors are dyeing uniformity, dye penetration and colour stability , it is indeed fundamentally essential that the fabric maintains its original colour over time.

Manufacturing Process

Following spinning and dyeing, the weaving process enables the yarn to intersect together to become fabrics. When the weft yarn crosses the warp yarn the fabric is created, a synthesis between the quality of the raw material, the creativity of the design, the structure and the experience of the weaver.

When the weft yarn crosses with the warp yarns a fabric is created, a synthesis of the quality of the raw material , the creativity of the design and the structure and experience of the weaver.

The weaving process consists of several phases, such as: winding, warping, sizing, drawing-in, weaving and finally the control on the greige fabric.

Manufacturing Process

Order confirmation is routed through CAD reference from customer. We prepare Desk loom as 1st reference sample & on its approval, yardages are confirmed. To run this pre-order segment, we have Sampling dept. It is a miniature production dept. As well, facilitated with collection card making activity. Skilled personnels carry out all the procedures to make collection for various clients. We launch collection in 2 seasons in a year.

5 Suzuki's and 36 weaving looms plus CCI (Handloom) Sampling dept receive finish fabric samples & convert them into collection cards, books & hangers in form of presentations to customers. These presentations are for design reference as well for fabric feel.

Manufacturing Process

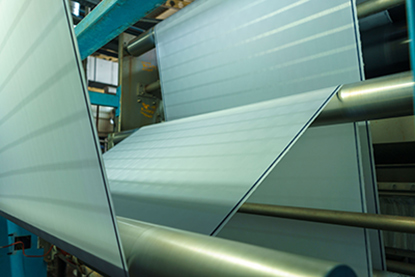

The textile finishing or “ennobling” is the group of treatments to which the fabric is subjected to improve the dyeability, printability, the hydrophilicity, the colour, the handle and the final appearance.

The various finishing processes are classified as follows: preparation, colouring (dyeing and printing), colour fastening and final finishing.

Ferno1913 have the best in class processing and finishing machines sourced from Switzerland, Germany and Italy.

Manufacturing Process

We inspect quality at 2 stages. Grey fabric & finish fabric. We do 100% inspection for grey as well as finish fabric for quality assessment. We have INCAS software to assure accuracy in fabric inspection. We follow 4 point grading system.

We establish a “Total Quality” framework to continually improve the quality Management System and realize challenging Quality objectives. Prevent defect outflow to next process and feedback to previous process for enhanced Quality Assurance.

Ferno1913 ensures that you get flawless, feather touch fabrics.